Fuel is a very precious natural resource that we always try to economise. In this context, research is being done to devise such engines that are fuel efficient. The benefits of saving the fuel are two-fold; one is economical and other is saving the environment. World Fuel reservoirs are running short of the demand as the consumption is increasing day by day. Keeping this shortage in view, the scientists are trying to invent such mechanisms that could save the fuel. In this regard, recently a Swedish scientist has proposed a new coating of Nano-particles which can save the fuel of jet aeroplanes. Furthermore, this coating lasts 3 times more as compared to aircraft engine coating currently in use.

The efficiency of the air jet also depends on the temperature of the engine, the more the temperature the more the efficiency. Taking this fact into account, the jet has to be the run at high temperature. To operate on such high temperature, the engines need to be shielded using heat coatings. These coatings are believed to increase the fuel efficiency.

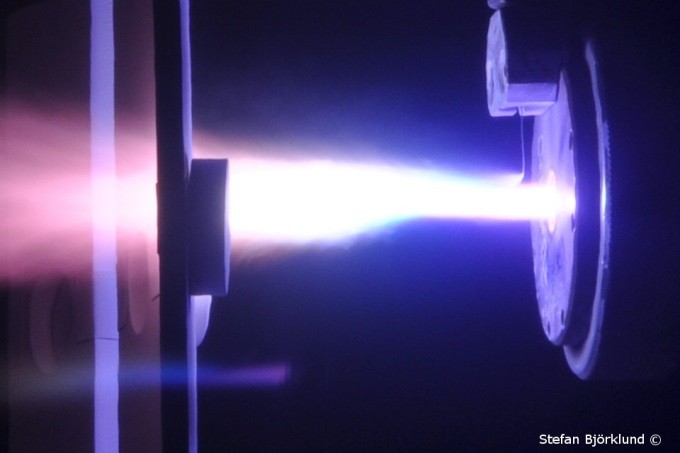

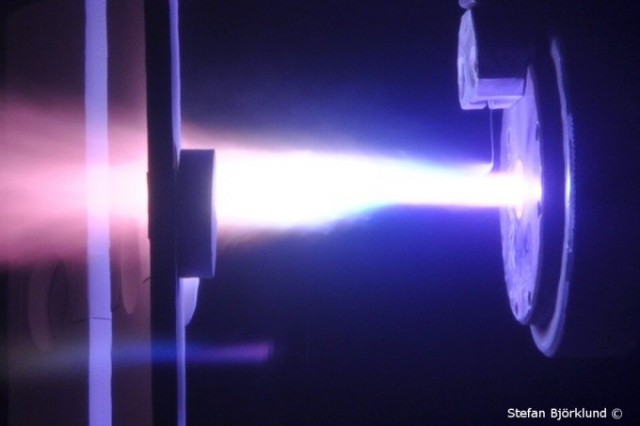

This coating is in the form of powder that consists of plastic and ceramics mixed in a liquid. The reason for adding plastic is to provide elasticity that’s important so that the metal on which it is applied could stretch and contract. The purpose of ceramic is to insulate the engine from intensive heat. The powder mixed in liquid is heated upto a temperature of 7000C to 8000C. This high temperature melts the ceramics and it sticks to the metal. The thickness of the coating is about 0.5 mm.

Unlike traditional coating that is sandwiched in the form of layers on the one side of metal. The newly designed structure is flexible and provides protection against cracking. This flexibility and cracking proof structure makes it good competitor for irregular shaped surfaces. During the shock experiments, this coating was found to have a three times more life as compared to earlier coatings. The coating is cheaper as compared to the current coating being used.

We might see this technology in future turbines and airplanes engines. This coating will play a vital role in saving fuel and saving the nature as well.